Our Scientific Basis

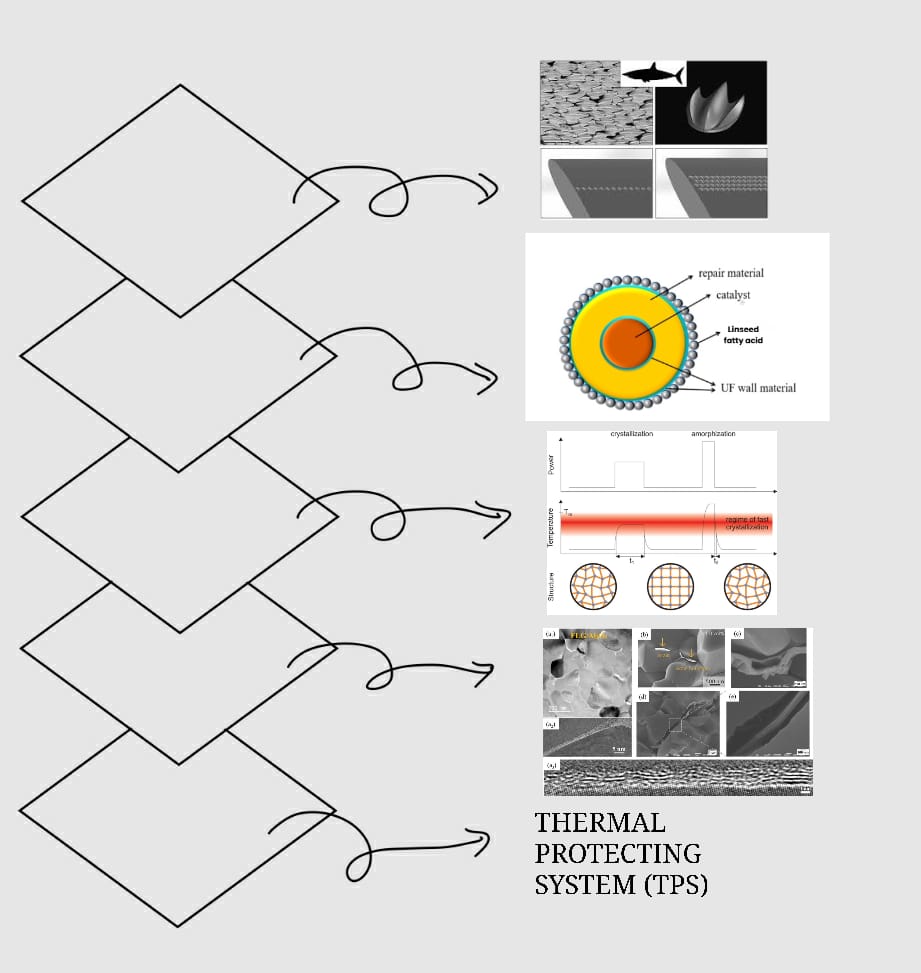

How to produce microcapsules with flaxseed?

The coating process with biological materials, such as flaxseed, which can self-renew, should be carried out

through microencapsulation, both for functional purposes and environmental sensitivity.

So, how are microcapsules obtained? A shell material is used for microencapsulation, such as urea-formaldehyde

(UF). Then, flaxseed oil is extracted, forming the core material of the microcapsules. Emulsifiers and

stabilizers are added. During the encapsulation phase, an in-situ polymerization method is used. Oil droplets

are created, and the polymer shell polymerizes around these droplets. Temperature and pH are controlled. With

these steps, flaxseed oil remains stable within the microcapsule. The shell structure protects the oil and

isolates it from the external environment. In the event of damage, the microcapsule is broken under mechanical

pressure, releasing the oil. The oil then fills the damage, comes into contact with oxygen in the air, and forms

a protective film through oxidation. In this way, a self-renewing mechanism is created.

How was the material selection made in the project?

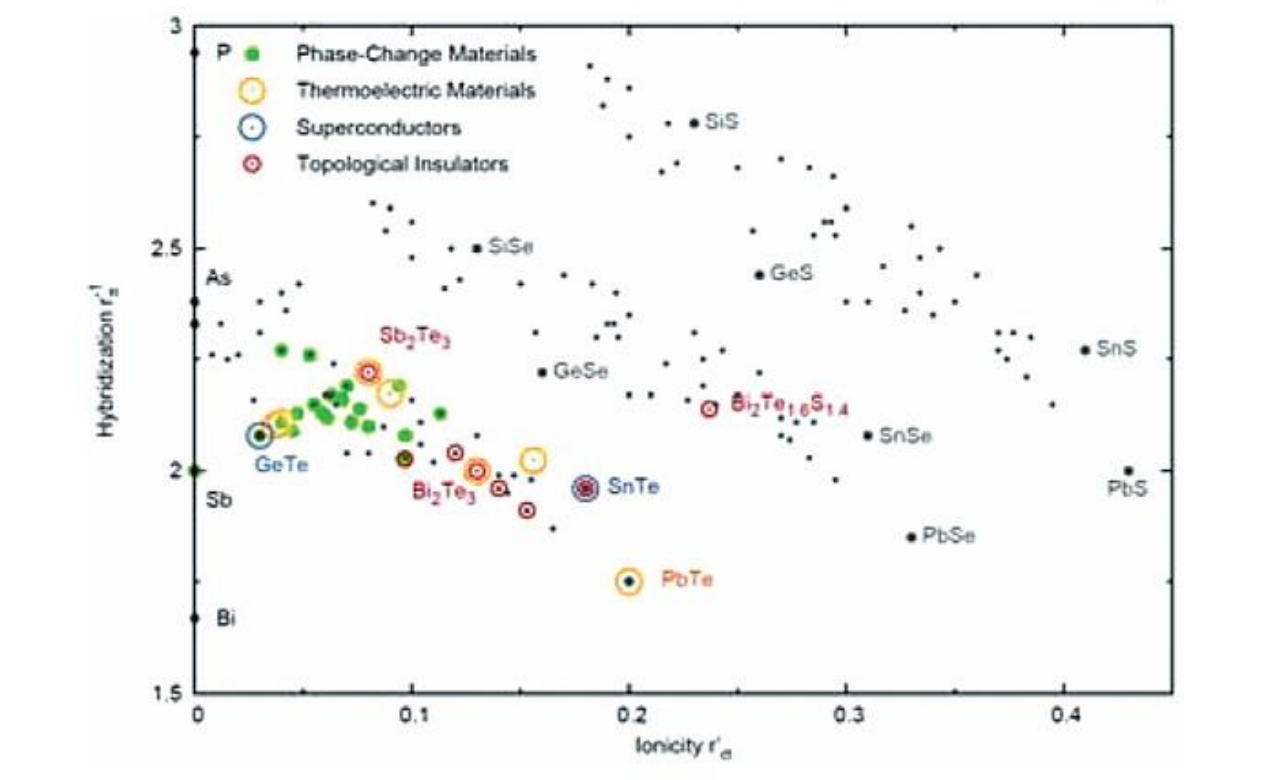

PCM (Phase Change Materials), are materials that can transition between two different phases (usually amorphous

and crystalline) within a specific temperature range. This transition leads to significant changes in the

material's physical properties, particularly in terms of optical and electrical characteristics.

Figure 1: PCM Materials Map showing Phase-Change Materials, Thermoelectric Materials, Superconductors, and Topological Insulators

Advantages of Graphene:

- Exceptional thermal conductivity (~5000 W/mK)

- Large surface area due to its 2D structure

- High mechanical strength

- Chemical stability

- Electronic properties can be tuned due to sp² hybridization

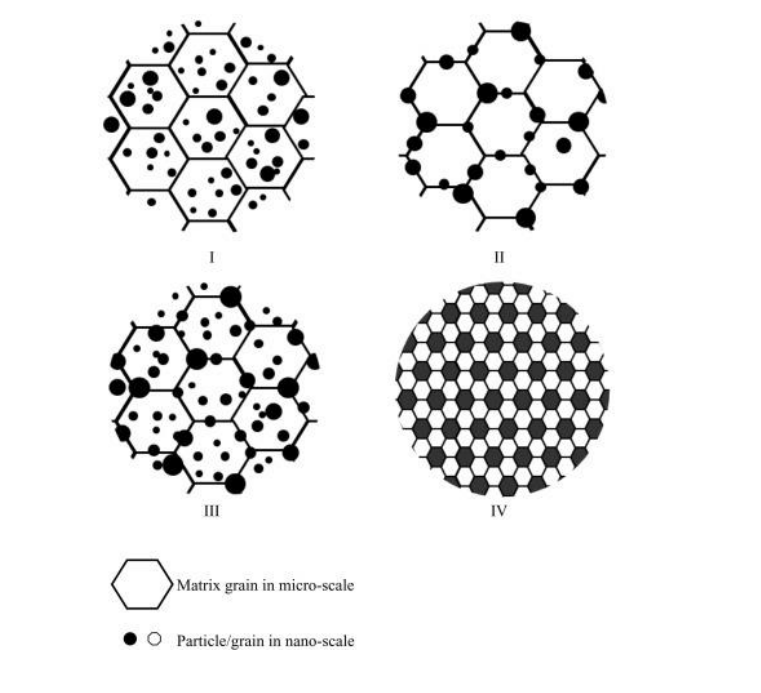

Figure 2: Different patterns of matrix grains showing micro-scale and nano-scale particle distributions

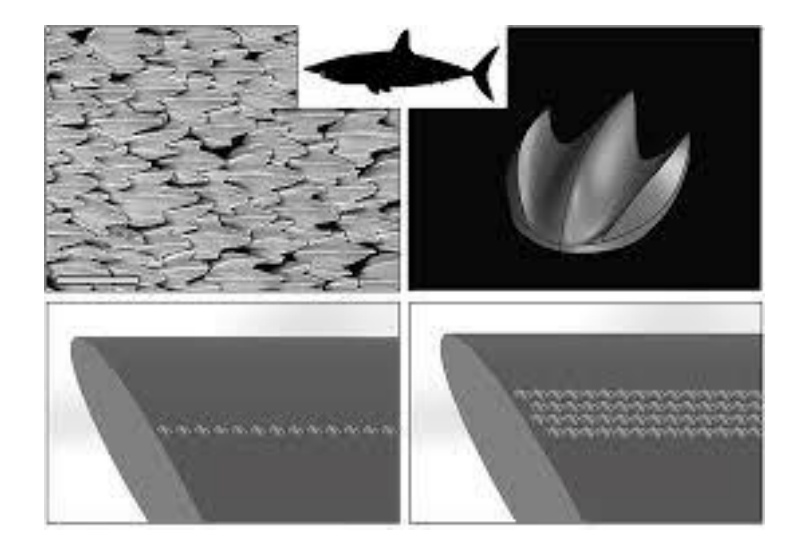

Principle of the Shark Skin Model

In this project, some of nature's remarkable designs have served as an inspiration for creating new technologies

that reduce friction. One such example is the shark skin model, which mimics a surface structure that minimizes

friction in nature.

Figure 3: Shark skin model illustration showing microscopic surface patterns and applications

Anti-Icing Surface: Lotus Effect and Application Methods

The Lotus leaf has a unique surface structure that allows water to quickly slide off the surface, preventing it

from sticking. When water droplets come into contact with the surface, they rapidly roll off. This effect is due

to microscopic surface structures that prevent water from adhering to the surface. The micro-textured structures

on the Lotus leaf ensure that water only touches the surface minimally, facilitating the movement of the droplet

and causing it to slide away without remaining on the surface.